I think.....you should consider making stuff you could selli'd be down with buying parts! thread is awesome enjoy coming to it and having a good read when on my lunch.

Thanks for sharing DDY

throw new ArgumentException (String, String, Exception)

Thanks for the all the comments.

I'll be posting an update on the (minor) improvements I've made to the printer later. But first;

I haven't until now bothered to do the maths

Assuming,

Each roll is 1kg

Density of PLA is 1350kg/m³ (I think)

Diameter of the filament is 3mm

Therefore, each roll should contain 105m of filament, more if the density of PLA is less than 1350kg/m³.

In perspective;

The quick release plate I printed in an earlier post consumed 3.2m of filament, note this was printed with a fill density factor of 0.8.

A single bracket printed for the trailing lead desk mount consumed 6.3m of filament, fill density factor was 0.5.

So, I should get a fair amount done with a single 1kg roll.

FYI, each 1kg roll costs £13 delivered.

Even though I've welded plastic using a soldering iron before, strangely I haven't thought about using a soldering iron for 3D prints, thanks for letting me know.

No, although I'm considering building my own CNC router. I decided the 3D printer should come first, because I could print things to build the former!

Hopefully there will be a "DDY's CNC router adventure" thread in the future

I intend to do a few one off design and prints but I haven't got any immediate plans for this yet.

As pointed out by TA there's no way I can manufacture parts on a commercial level with the kit I have.

Building one would certainly be cheaper.

In theory I could simply replace the extruder on my 3D printer with a Dremel and with a bit of tinkering with the controller have my own CNC router.

Or, I could 3D print one

I use a number of Slic3r settings depending on the job. I've found that unless there are complex or delicate parts on the first layer of a print job, Slic3r settings don't do much to help. The obvious thing to try is to reduce the first layer print speed, I use about 15mm/s for the most delicate parts, e.g. small circles.

Outside of Slic3r, here are some suggestions:

- Reduce the nozzle clearance to 0.2mm or slightly less, i.e. lowered from the .25mm suggested by Velleman. A feeler gauge set would help.

- Blue painters tape or Kapton tape, this helps the filament stick

- Flattening the bed, I did this by placing an Ikea SÖRLI mirror atop the existing bed and securing it with binder clips

- Preheating the bed manually to +50°C for a few minutes before a print job.

- Priming the nozzle by pre-heating the nozzle and manually extruding a few mm of filament right before a print, don't forget to get rid of the extruded filament though! This helps get rid of the slow and thin extrusion of the first few centimetres of filament before the print job.

Last edited by DDY; 03-05-2014 at 07:16 PM.

Always fancied going for this myelf but never wanted to deal with the problems, glad you're brave/stupid enough

So....companion cube done, what about a turret?

Ker bump!

Prompted by a HEXUS article showing how sales of desktop 3D printers is growing, so recalling this thread, I was wondering if there was any update?

(\__/)

(='.'=)

(")_(")

Been helped or just 'Like' a post? Use the Thanks button!

My broadband speed - 750 Meganibbles/minute

I would like a 3D printer but I think I would probably pay a fair bit of money for something I would use once in a blue moon, and it would end up gathering dust like many other things bought over the years. Fantastic idea though if its something you can make use of.

Jon

I've actually been doing a lot of 3D printing since my last post, I'd love to share my project logs but not only am I really bad at documenting my projects, I've also been very busy on jobs away from home. I've now gone back to university to do a masters and unfortunately I don't have enough space for a 3D printer in student digs.

Here are some photos that I could find of the more interesting projects I've done;

This is my attempt at a cloud chamber which I only got as far as building the cold plate and sorting out a chassis - before I left for uni. Not very 3D printing intensive, but the 3D printed parts were invaluable in bodging salvaged bits together.

Here's a very 3D printing intensive project, a 100W LED flashlight with a big lipo in the back, completed back in 2014, way before these things became a thing on Youtube.

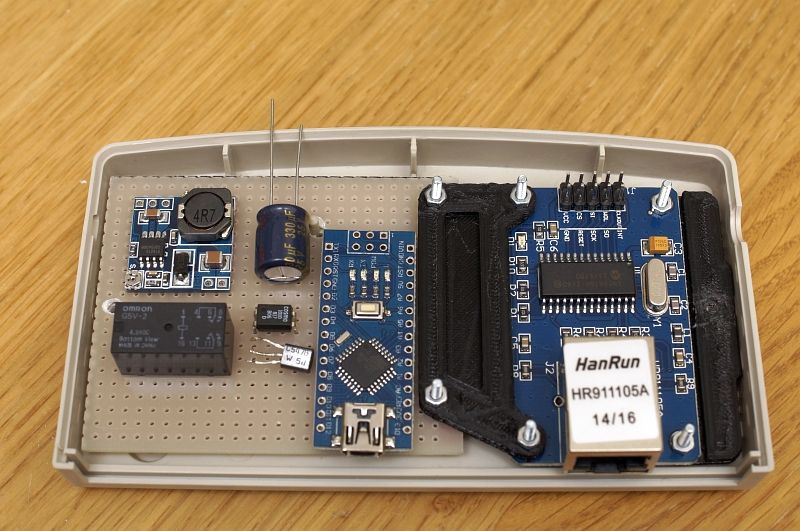

The very last thing I 3D printed, a few brackets and a rear plate for a repurposed network switch case, which now houses the thing that momentarily kills the power to my Virgin Superhub, thereby rebooting it, if the internet connection goes down.

There are currently 1 users browsing this thread. (0 members and 1 guests)